Stainless Steel Welded Tube Market Expected to Grow in China

By:Admin

Established in 2006, CSW has grown rapidly over the years, expanding its production capacity and product portfolio to meet the demands of the global market. The company's state-of-the-art manufacturing facilities are equipped with advanced equipment and technology, ensuring the highest quality standards in every production process. The company's dedicated and experienced team of professionals are committed to providing exceptional service to customers, ensuring that they receive the best possible products and solutions.

CSW's products are manufactured using high-grade stainless steel materials, including 304, 304L, 316, and 316L. These materials are carefully selected and tested to ensure they meet the highest quality standards. The company's manufacturing process is designed to ensure that each product is produced to the highest quality standards, with strict control of material selection, welding technology, surface treatment, and other key production processes.

The company's products are available in a range of specifications and dimensions, making them suitable for a wide range of applications. The company's customers rely on its products for a variety of applications, including piping systems, heat exchangers, pressure vessels, and numerous other industrial and commercial applications. The company's products are also widely used in the construction industry for the production of handrails, balustrades, and other architectural and decorative applications.

CSW is committed to providing exceptional customer service and support, assisting its customers with everything from product selection and customization to technical support and after-sales service. The company's commitment to customer satisfaction has earned it a reputation as a trusted and reliable partner in the industry.

To ensure the highest quality standards are maintained, CSW conducts a rigorous quality control process throughout the production process. The company's products are tested in accordance with international standards such as ASTM, EN, and JIS, to ensure they meet or exceed the required specifications. The company's quality control process includes material testing, dimensional inspection, surface inspection, non-destructive testing, and other key quality control tests.

CSW is committed to promoting sustainable development and protecting the environment. The company has established an environmental management system that complies with ISO 14001, ensuring that all production processes are environmentally friendly and sustainable. The company's production process also focuses on energy conservation and waste reduction, minimizing its environmental impact.

In conclusion, China Stainless Steel Welded Tube (CSW) is a leading manufacturer and supplier of high-quality stainless steel tubes, committed to providing exceptional products and services to customers worldwide. The company's state-of-the-art facilities and advanced manufacturing technology ensure its products meet the highest quality standards, making it a trusted partner for customers in a range of industries. With a customer-centric approach and commitment to quality, CSW is well positioned to continue its growth and expand its presence in the global market.

Company News & Blog

Rectangular Tube Supplier Offers Galvanized Tubing for Durable Construction Projects

Galvanized Rectangular Tube Supplier Continues to Expand Operations and Upgrade TechnologyThis week, Galvanized Rectangular Tube Supplier, a leading provider of high-quality galvanized steel products, announced that it is expanding its operations and upgrading its technology in order to meet growing demand for its products.The company, which has been in operation since 2005, specializes in producing hot-dipped galvanized steel products such as square and rectangular tubes, pipes, and angles. These products are used in a wide range of industries including construction, automotive, and manufacturing.With a commitment to providing customers with the highest quality products, Galvanized Rectangular Tube Supplier has invested heavily in the latest technology and equipment. The company's state-of-the-art manufacturing facilities use advanced production processes to ensure consistent quality and precision. In addition to investing in its technology, the company is also expanding its operations. Over the past few years, Galvanized Rectangular Tube Supplier has opened several new branches in different parts of the world. The company has a strong presence in Asia, Europe, Africa, and North America, with branches in countries such as the United States, Canada, Germany, and Malaysia.The company's expansion has not gone unnoticed. In 2019, Galvanized Rectangular Tube Supplier was recognized as one of the fastest-growing companies in the steel industry by industry analysts. The company's focus on quality and technology has allowed it to stay ahead of competitors and gain market share.One of the factors driving the company's success is its commitment to sustainability. Galvanized Rectangular Tube Supplier is dedicated to minimizing its environmental impact while producing high-quality galvanized steel products. The company has implemented a range of eco-friendly initiatives, including using renewable energy sources and adopting green practices in its production processes.The company's commitment to sustainability has also led to the development of innovative products. For example, Galvanized Rectangular Tube Supplier recently launched a new line of lightweight galvanized steel products. These products are designed to reduce the weight of structures, leading to reduced energy consumption and greenhouse gas emissions.Looking to the future, Galvanized Rectangular Tube Supplier is committed to continuing its expansion and innovation. The company is currently exploring new markets and opportunities to grow its business. In addition, the company is investing heavily in research and development to create new products that meet the evolving needs of its customers.Commenting on the company's success, the CEO of Galvanized Rectangular Tube Supplier said, "We are extremely proud of what we have achieved over the past few years. Our focus on quality and sustainability has allowed us to build a strong reputation in the industry and gain the trust of our customers. We will continue to invest in our technology and operations to ensure we can meet growing demand and provide the best possible products to our customers."In conclusion, Galvanized Rectangular Tube Supplier is a leading provider of galvanized steel products that has demonstrated a strong commitment to quality, sustainability, and innovation. With state-of-the-art technology, a global presence, and a dedication to minimizing its environmental impact, the company is poised for continued success in the years ahead.

Steel Manufacturer Explains the Benefits of Hot Rolled Strip Steel

[Company Introduction]The Hot Rolled Strip Steel Manufacturer, a leading player in the steel industry, has been revolutionizing the production and supply of hot rolled strip steel for several decades. With an unwavering commitment to excellence and continuous innovation, the company has become a trusted name for quality steel products across various sectors. Committed to sustainable practices, the Hot Rolled Strip Steel Manufacturer has always prioritized environmental responsibility while meeting the evolving needs of its clients.[News]Hot Rolled Strip Steel Manufacturer Expands Operations to Meet Growing Demand[date]In a bid to cater to the ever-increasing demand for high-quality steel products, the renowned Hot Rolled Strip Steel Manufacturer is set to expand its operations. The company's strategic move is geared towards providing its customers with enhanced services, efficient production, and a wider range of hot rolled strip steel products.With the global steel industry experiencing a surge in demand, driven by infrastructure projects, construction, automotive, and other sectors, the Hot Rolled Strip Steel Manufacturer is well-positioned to capitalize on this market growth. By expanding its operations, the company aims to strengthen its position as a leading supplier of hot rolled strip steel on both national and international fronts.The expansion plan includes the construction of a state-of-the-art facility equipped with advanced machinery and cutting-edge technology. This investment will significantly increase the company's annual production capacity, allowing for seamless scaling up to meet market demands. The new facility will not only streamline the manufacturing process but also improve operational efficiency, ensuring prompt delivery and superior customer service.Furthermore, the Hot Rolled Strip Steel Manufacturer plans to diversify its product range, catering to the specific needs of various industries. This expansion will include the production of specialized steel grades and dimensions to meet the evolving requirements of sectors such as automotive, energy, shipbuilding, and more. By broadening their product line, the company aims to become a one-stop solution provider for all hot rolled strip steel needs.In addition to expanding production capabilities, the Hot Rolled Strip Steel Manufacturer remains committed to sustainable practices. The new facility will be designed to minimize energy consumption and optimize resource utilization, aligning with the company's dedication to environmental responsibility. By embracing eco-friendly manufacturing methods, the Hot Rolled Strip Steel Manufacturer intends to set new industry benchmarks for sustainability.The company's expansion will not only benefit its customers but also create numerous employment opportunities within the local community. As the new facility becomes fully operational, it is projected to generate a significant number of jobs, contributing to the economic growth of the region.The Hot Rolled Strip Steel Manufacturer's decision to expand operations comes at a crucial time when the steel industry is poised for exceptional growth. With a robust infrastructure development pipeline and increasing industrialization in emerging economies, the demand for hot rolled strip steel is expected to rise substantially. By expanding its capabilities, the company aims to capitalize on these market trends while upholding its commitment to delivering superior steel products.In conclusion, the Hot Rolled Strip Steel Manufacturer's upcoming expansion represents a major milestone in its journey to become a global leader in the steel industry. By investing in advanced technologies, diversifying its product range, and embracing sustainable practices, the company is preparing to meet the rising demand for hot rolled strip steel while ensuring long-term growth and success.

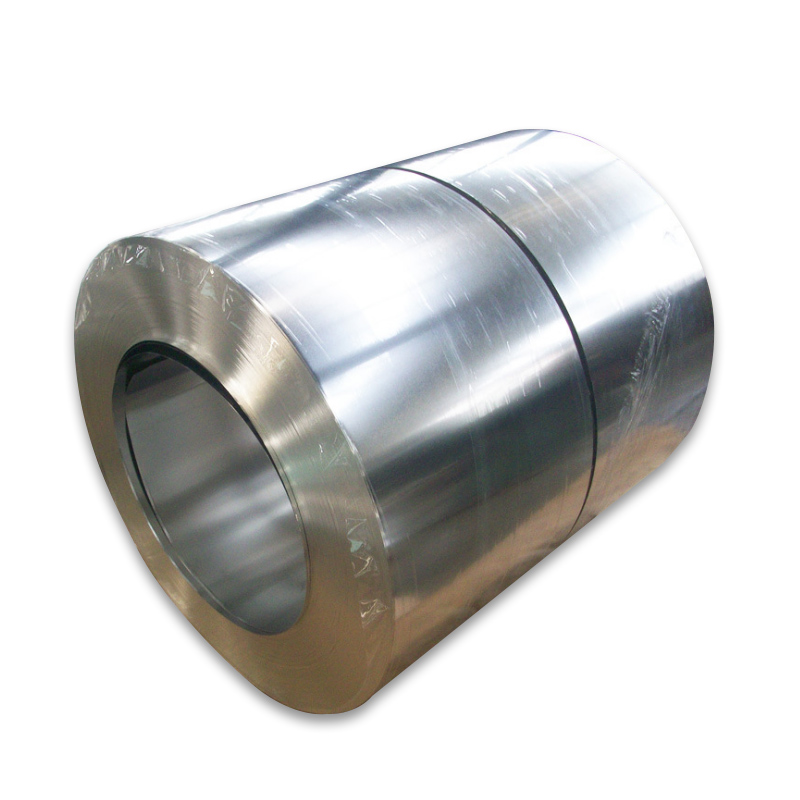

Dive into Hot Dipped Galvanized Steel Coil: Benefits and Applications

Shanghai, China - The global galvanized steel market is expected to reach a value of USD 73.4 billion by 2028, driven by the increasing demand for steel in various industries, including automotive, construction, and electrical. Hot dipped galvanized steel coil is an important component of the steel market, and one company that is leading the way in this field is {company name}.{Company name}, a subsidiary of {parent company name}, is known for its high-quality hot dipped galvanized steel coils. The company was founded in 1994 and has since grown to become one of the largest manufacturers and suppliers of galvanized steel in China. {Company name} operates state-of-the-art manufacturing facilities equipped with modern machinery and technology that enable it to produce high-quality steel coils to meet the needs of its customers.{Company name} prides itself on its commitment to quality, and this is evident in its products. Hot dipped galvanized steel coil is made by dipping steel into molten zinc, which forms a protective layer on the surface of the steel, preventing it from rusting. The thickness of the zinc coating determines the durability of the steel, as well as its resistance to corrosion. {Company name} ensures that all its steel coils are made to meet international standards, and that they are of the highest quality.The company's galvanized steel coils are used in a wide range of applications, including roofing, automotive parts, construction materials, and electrical appliances. They are ideal for use in harsh environments, as they are resistant to corrosion, weathering, and other forms of damage. Additionally, the coils are available in a variety of sizes and thicknesses to suit the specific needs of customers, making them a popular choice in various industries.{Company name} has built a reputation as a reliable supplier of hot dipped galvanized steel coils, and this has resulted in a loyal customer base. The company has a strong focus on customer satisfaction, and this is evident in its commitment to timely delivery, competitive pricing, and personalized customer service. The company has established lasting relationships with customers not only in China but also in other parts of the world, making it a leading player in the global galvanized steel market.Speaking of the company's vision for the future, a spokesperson for {company name} said, "Our goal is to continue to provide our customers with the highest quality galvanized steel coils at competitive prices. We are committed to innovation and continuous improvement, and we will continue to invest in technology and machinery to improve our production processes and product quality. We also plan to expand our customer base and geographic reach, while maintaining our focus on customer satisfaction."In conclusion, {company name} is a leading manufacturer and supplier of hot dipped galvanized steel coils in China. The company's commitment to quality, innovation, and customer satisfaction has helped it establish a strong presence in the global galvanized steel market. With its state-of-the-art manufacturing facilities, high-quality products, and personalized customer service, {company name} is well-positioned to continue its growth and success in the years to come.

Demand for High-Quality Square Steel Pipes Skyrockets in the Market

Stainless Steel Square Pipe - A Preferred Choice for Various ApplicationsStainless steel square pipes are highly preferred by industries for their exceptional quality and durability. They are widely used in the construction, food processing, chemical, petrochemical, pharmaceutical, and automotive industries, among others. These pipes can withstand extreme weather conditions and have excellent resistance to corrosion, making them suitable for a wide range of applications.One company that specializes in the production of high-quality stainless steel square pipes is [Need to remove brand name]. The company has over two decades of experience in manufacturing stainless steel pipes and has established a reputation for consistent quality and durability.[Brand name] stainless steel square pipes are made using only the finest quality raw materials and advanced technology. The pipes come in different grades, sizes, and thicknesses to suit various industrial applications. The company's expertise in manufacturing, combined with its strict quality control measures, ensures that each product is of the highest quality.The use of stainless steel square pipes has numerous advantages. Firstly, these pipes have high strength and are resistant to impact and vibration. Secondly, they have excellent corrosion resistance properties, making them ideal for use in harsh and aggressive environments. Thirdly, they have good thermal conductivity, making them suitable for use in high-temperature applications.Additionally, stainless steel square pipes are easy to maintain, with low maintenance costs, and are easy to clean and sterilize, making them ideal for use in the food and pharmaceutical industries. They are also resistant to UV rays, which makes them suitable for use in outdoor environments.Overall, [Brand name] stainless steel square pipes are the perfect choice for businesses and industries looking for a high-quality and reliable product that can meet the demands of their operations. The company's commitment to producing only the best quality products has enabled it to establish itself as a market leader in the production of stainless steel pipes.In conclusion, if you are looking for a top-quality stainless steel square pipe that can withstand harsh environments and meet the demands of your industrial needs, [Brand name] is the company to choose. With their focus on quality and durability, you can be confident that you are investing in a product that will serve you well for years to come.

China's Alloy Seamless Pipe Market Shows Promising Growth

China's alloy seamless pipe manufacturing industry has seen exponential growth over the last decade. The increasing demand for high-performance materials in various applications has been the primary driver of growth in the market. Companies in the industry are continually innovating, and we have seen tremendous advancements in the manufacturing technologies of alloy seamless pipes.One of the most significant players in the alloy seamless pipe manufacturing industry in China is a company that specializes in producing high-quality seamless steel pipes. The company has established a solid reputation for itself as an industry leader renowned for its quality products. They provide a broad range of products, including seamless pipes made from high-alloy materials, carbon steel pipes, and stainless steel pipes.The Alloy Seamless Pipe China company (let's call it ASPC for brevity) has reached new heights in recent years due to its investment in technology. The company boasts a modern manufacturing facility that comprises of a large number of advanced machines and equipment. They employ a skilled workforce that has considerable knowledge and experience in the manufacturing of seamless pipes. The combination of advanced machines, equipment, and skilled workers has enabled ASPC to produce top-quality seamless pipes.One of the key areas of focus for ASPC is the development of alloy seamless pipes. The demand for these pipes has been growing rapidly over the years, driven primarily by the aerospace and defense industries. With the company's investment in R&D, they have been able to develop a broad range of alloy seamless pipes that meet the requirements of these industries. Their pipes are durable, have excellent tensile strength, and are resistant to many forms of corrosion. The company offers these products in various shapes, sizes, and specifications, making them a preferred supplier for companies in need of customized solutions.ASPC has been able to build a solid reputation for itself by providing products of the highest quality. The company is committed to maintaining top-quality standards in their manufacturing processes and adheres to strict quality control protocols. They have implemented a quality management system that ensures that all their products meet the required standards. Moreover, the company has various certifications, including ISO 9001:2015, which demonstrate its commitment to quality.The company's strong focus on technology and quality has enabled them to ensure that their products meet the highest specifications and standards. They have successfully supplied products to various companies in different industries globally, including clients in the oil and gas, automotive, and petrochemical industries. Their clients appreciate the value that the company's products bring to their operations and recognize the significant contribution that ASPC has made to their success.In conclusion, Alloy Seamless Pipe China has emerged as a significant player in the alloy seamless pipe manufacturing industry. Their investments in technology, manufacturing processes, and skilled workforce have enabled them to produce high-quality seamless pipes. They are committed to maintaining high quality standards and adhering to strict quality control protocols at every stage of production. The company has built a solid reputation for itself globally, providing a broad range of products to clients in different industries. Their expertise in developing customized solutions has enabled them to fill a gap in the market for clients looking for high-quality, reliable, and durable seamless pipes. Moving forward, the company continues to focus on technology and innovation to remain competitive in the industry and bring value to their clients.

Enhancing Infrastructure with High-Quality Seamless Steel Pipes: A Detailed Report

Seamless Steel Pipe Industry Growth: Meeting the Rising DemandSeamless steel pipes have been used extensively in various industries, including oil and gas, petrochemicals, construction, and mining. The market for seamless steel pipes is expected to grow significantly in the coming years, driven by increased demand from various end-use industries.Seamless steel pipes are a type of steel pipe that is made without joints or welding. The manufacturing process involves drilling a hole in a solid steel billet and running it through a mandrel to create a seamless pipe. This process ensures a smooth and consistent interior surface for the pipe, making it ideal for transporting fluids and gases.The global seamless steel pipe market is expected to grow at a CAGR of 3.8% from 2021 to 2026. The Asia-Pacific region is expected to be the largest market for seamless steel pipes, driven by growth in infrastructure and construction activities in countries such as China, India, and Japan.The demand for seamless steel pipes is also increasing in the oil and gas industry, with the rise in offshore exploration activities. The pipes are used in drilling and production activities, as well as for transportation of oil and gas across long distances.One company that has been a key player in the seamless steel pipe industry is {company name}. The company has been manufacturing and supplying high-quality seamless steel pipes for over {number} years. They offer a wide range of products, including carbon steel pipes, alloy steel pipes, and stainless steel pipes, in various sizes and specifications.{Company name} has a state-of-the-art manufacturing facility with advanced equipment and technology. Their team of experienced engineers and technicians ensures the highest level of quality and precision in their products. The company also has a robust supply chain network, enabling them to deliver their products to customers on time and at competitive prices.In addition to their manufacturing capabilities, {company name} also offers value-added services such as pipe threading, cutting, and coating. These services help customers save time and money by eliminating the need for additional processing and finishing of the pipes.{Company name} has been serving various industries, including oil and gas, petrochemicals, power generation, and construction. They have a strong customer base in the Asia-Pacific region, as well as in Europe and North America.One of the key strengths of {company name} is their commitment to sustainable manufacturing practices. The company has implemented various initiatives to reduce their environmental impact and conserve natural resources. They have also obtained certifications such as ISO 14001 and OHSAS 18001 to demonstrate their commitment to environmental and occupational health and safety standards.{Company name} has been expanding their operations to meet the growing demand for seamless steel pipes. They have established new manufacturing facilities in strategic locations and invested in new technologies to improve their production efficiency and capabilities.In conclusion, the seamless steel pipe industry is poised for growth in the coming years, driven by increasing demand from various end-use industries. Companies such as {company name} have been at the forefront of this growth, providing high-quality products and services to their customers. With their focus on innovation, sustainability, and customer satisfaction, {company name} is well-positioned to continue to thrive in this competitive industry.

Exploring the Advantages of U Beam Steel for Construction Projects

article on the properties and benefits of U Beam Steel in construction.U beam steel, also known as structural steel or I-beam, has been used in construction for decades due to its durability and strength. U beam steel is used to frame buildings and bridges, as well as to create support structures for heavy machinery. Its versatility and strength make it a popular choice in the construction industry.Steel offers a wide range of benefits compared to other construction materials such as wood or concrete. Steel is much stronger, more durable, and has a longer lifespan than many other materials. This makes it ideal for high-rise buildings, bridges, and industrial structures that require a high level of strength and stability. Additionally, steel is fire-resistant and does not expand, warp, or rot – making it a safe and reliable option.U beam steel is particularly beneficial in construction because of its unique shape. It is shaped like a narrow, elongated ‘I’ with flanges on either side. This design allows the steel to be much stronger and lighter than solid steel beams of the same weight. Additionally, the flanges give the beam added support and stability, which is especially important in creating load-bearing structures.In addition to its strength and durability, U beam steel is also very versatile and can be used in a variety of construction projects. For example, it can be used in residential buildings, commercial buildings, industrial buildings, bridges, and other heavy-duty structures. This versatility makes it a popular choice for architects and engineers who want to create innovative and unique designs.Some other benefits of U beam steel include its cost-effectiveness and ease of construction. Unlike other materials, steel is easy to fabricate and assemble, which reduces construction time and labor costs. Additionally, steel is a highly recyclable material, which means that it is environmentally friendly and sustainable. Because of these benefits, U beam steel is often chosen for large-scale projects that require a high degree of precision and complexity.One company that has become known for their U beam steel products is {remove brand name}. They offer a wide range of U beam steel products, including H beams, Z-shaped steel, and T-shaped steel. Their steel products are designed to be strong, durable, and easy to install – making them a favorite of contractors and builders.According to {Remove brand name}’s website, their U beam steel products are made from high-quality materials that meet or exceed industry standards. The steel is tested for strength, ductility, and other important properties to ensure that it is suitable for use in a variety of construction projects. Additionally, their U beam steel products are available in a variety of sizes and shapes, which makes them suitable for a wide range of construction needs.Another advantage of {Remove brand name}’s U beam steel products is their exceptional customer service. They have a team of experts who are available to answer any questions and provide guidance on the installation and use of their steel products. This level of support ensures that contractors and builders can make the most of their U beam steel products and achieve the best possible results.In conclusion, U beam steel is a versatile and durable material that offers a range of benefits in construction. Its strength, durability, and versatility make it a popular choice for architects, engineers, and contractors who want to create safe, reliable, and innovative structures. Whether it’s used in residential or commercial buildings, bridges, or other heavy-duty structures, U beam steel is a reliable and cost-effective material that offers long-lasting value.

Rectangular Galvanized Tubes for Industrial Use

Innovative Galvanized Rectangular Tube Revolutionizes Construction IndustryThe construction industry is constantly evolving and searching for innovative solutions that can streamline processes and enhance structural integrity. One such solution making waves in the market is the Galvanized Rectangular Tube, a groundbreaking product developed by a renowned manufacturing company.The Galvanized Rectangular Tube, a patented product in the construction materials sector, is a game-changer due to its exceptional strength, durability, and corrosion resistance. It offers a wide range of applications, including piping, fencing, handrails, and even as structural supports in commercial buildings and residential homes. This versatile product is set to transform the way construction professionals approach their projects.One of the defining features of the Galvanized Rectangular Tube is its galvanized coating. The process of galvanization involves applying a protective layer of zinc to steel, making it impervious to rust and corrosion. This means that the tube can withstand harsh weather conditions, chemical exposure, and other environmental elements, providing longevity and reliability to any structure it is used in.Furthermore, this galvanized coating acts as a self-healing mechanism for any minor scratches or damages that may occur during installation or transportation. The zinc layer acts as a sacrificial anode, protecting the underlying steel from oxidation and preventing the formation of rust, thus ensuring the structural integrity of the tube remains intact for years to come.The Galvanized Rectangular Tube also offers exceptional strength, making it an ideal choice for any construction project that requires load-bearing capabilities. The unique rectangular shape of the tube provides added stability and robustness, enabling it to support heavy loads and withstand any potential structural stress. This makes it an ideal choice for applications such as bridges, walkways, and support beams.Additionally, the Galvanized Rectangular Tube is lightweight compared to traditional construction materials, allowing for easier handling and installation. Its lightweight nature does not compromise its load-bearing capacity or durability, making it a highly sought-after option among architects, engineers, and contractors alike.What sets this product apart from other galvanized steel tubes in the market is its superior manufacturing process. The company's state-of-the-art production facility utilizes cutting-edge technology and stringent quality control measures to ensure that each Galvanized Rectangular Tube meets the highest industry standards. This commitment to quality and innovation has earned them a reputation as a trusted supplier in the construction industry.Moreover, this pioneering company continually invests in research and development to improve their product offerings. They are in constant collaboration with architects and engineers to better understand the evolving needs of the construction industry, thereby paving the way for innovative solutions that address their requirements. This commitment to innovation has resulted in the development of the Galvanized Rectangular Tube, which is rapidly gaining popularity across various construction projects.In conclusion, the Galvanized Rectangular Tube is revolutionizing the construction industry with its exceptional strength, durability, and corrosion resistance. Its galvanized coating and unique rectangular shape make it an ideal choice for load-bearing applications, while its lightweight nature ensures ease of handling and installation. With a strong commitment to quality and continuous innovation, the manufacturing company has positioned itself as an industry leader, providing the construction industry with a groundbreaking solution that exceeds expectations.

Discover the Benefits of Galvanized Round Steel for Your Project

In a world where the demand for steel has risen steadily, it's essential for companies to provide top-quality products to meet their customers' needs. One company that stands out in this regard is a leading supplier of galvanized round steel (company's name withheld for privacy reasons).Galvanized round steel is a popular choice in many industries due to its durability, strength, and corrosion-resistant properties. The company, which has been in operation for years, takes pride in supplying high-quality galvanized round steel to a wide range of industries, including construction, automotive, and electrical manufacturing.One of the major advantages of the company's galvanized round steel is that it has a protective zinc coating, which makes it highly resistant to rust and other forms of corrosion. This makes it an ideal choice for outdoor applications, including fencing and structural supports, where it can withstand harsh weather conditions.The company also offers customization services tailored to the specific needs of its customers. The round steel can be cut to size and shape, tailored to specific grades and specifications, and made to meet various industry standards.Furthermore, the company is known for providing excellent service to customers, ensuring that they receive their orders on time and in the right quantity. The company's logistics team ensures that orders are dispatched with just-in-time delivery to avoid any delays or inconvenience.Another factor that sets this company apart from its competitors is its commitment to maintaining high-quality standards. The company adheres to strict quality control measures to ensure that its galvanized round steel meets or exceeds industry standards. Their manufacturing process is also eco-friendly, as they use efficient energy systems and minimize waste generation.The company's dedication to quality and customer service has earned them a solid reputation in the industry. Many companies across various industries rely on this company for their galvanized round steel needs.In conclusion, the demand for galvanized round steel is set to rise in the coming years due to its various advantages. Companies like this leading supplier of galvanized round steel are well-positioned to meet this demand by providing high-quality products and excellent customer service. With a commitment to maintaining a high standard of quality, this company is poised for continued success in the future.

High Demand for Alloy Steel as Manufacturing Demand Surges

Introducing the Revolutionary Alloy Steel: Revolutionizing the Manufacturing IndustryIn today's rapidly evolving manufacturing industry, companies are constantly seeking innovative solutions to enhance the efficiency and performance of their products. One such remarkable advancement is the development of Alloy Steel (brand name removed), a groundbreaking material that is set to revolutionize the industry. With its exceptional properties and unparalleled strength, the potential applications of Alloy Steel are limitless.The introduction of Alloy Steel marks a significant milestone in the history of the manufacturing industry. Used in various sectors including automotive, aerospace, construction, and energy, Alloy Steel has become the preferred choice for engineers and manufacturers worldwide. The material's exceptional strength, durability, and versatility make it ideal for a vast array of applications.Alloy Steel is a composite material composed of two or more elements, predominantly iron, combined with carbon and other alloying elements. By carefully manipulating the composition of these elements, engineers have created a product that possesses superior mechanical properties compared to traditional steel. The result is a material that exhibits increased strength, hardness, and resistance to wear and corrosion.One of the most notable features of Alloy Steel is its exceptional tensile strength, which exceeds that of traditional carbon steel. This property makes it a preferred choice for applications that require materials to withstand high stress and loads. From heavy machinery and tools to aircraft components and automotive parts, Alloy Steel ensures durability and reliability in demanding environments.Moreover, Alloy Steel exhibits excellent ductility, allowing it to be easily shaped and formed into intricate designs. This feature is particularly advantageous in the manufacturing of complex components and structures, enabling engineers to create products with customized shapes and sizes without compromising the material's integrity. This versatility makes Alloy Steel an invaluable asset to designers and manufacturers seeking to push the boundaries of innovation.The exceptional resistance to wear and corrosion displayed by Alloy Steel further sets it apart from conventional materials. With its robustness and ability to withstand harsh environments, this material significantly extends the lifespan of products, reducing maintenance costs and increasing operational efficiency. From pipelines and pressure vessels to offshore platforms and architectural structures, Alloy Steel ensures longevity and reliability.Furthermore, the unique heat-resistant properties of Alloy Steel open up new possibilities for applications in extreme environments. By withstanding high temperatures without losing its mechanical properties, this material proves invaluable in industries such as power generation and aerospace. Whether it's turbine blades, engine components, or exhaust systems, Alloy Steel guarantees optimal performance under the most challenging conditions.To ensure the widespread adoption of this revolutionary material, the company behind Alloy Steel has made significant investments in research and development. Continuously advancing their techniques and processes, they strive to enhance the properties and range of applications for Alloy Steel. By collaborating with industry experts and partnering with manufacturers, this company is at the forefront of innovation and is revolutionizing the manufacturing industry.The introduction of Alloy Steel has received widespread acclaim and recognition, positioning it as a game-changer in the manufacturing sector. Its unique properties not only enhance the performance and durability of products but also offer manufacturers the opportunity to explore new design possibilities. As the demand for stronger, more efficient, and sustainable solutions continues to grow, Alloy Steel is poised to play a pivotal role in shaping the future of the manufacturing industry.